Filament Printing

I have some experience with 3D printing. I did some research in my undergraduate degree concerning the potential for novel biomedical applications of additive manufacturing, I took a graduate level course in education through 3D printing, and I’ve always had a bit of a fascination with hit. So when I was given a TronXY X5SA FDM machine for Christmas of 2021, I was excited.

However, I have struggled greatly with this printer. It seems to mostly be a derivative product from a Chinese company whose manuals have the tell-tale signs of being poorly translated. The quality control of the product was poor and I have been frustrated through assembly and early operation.

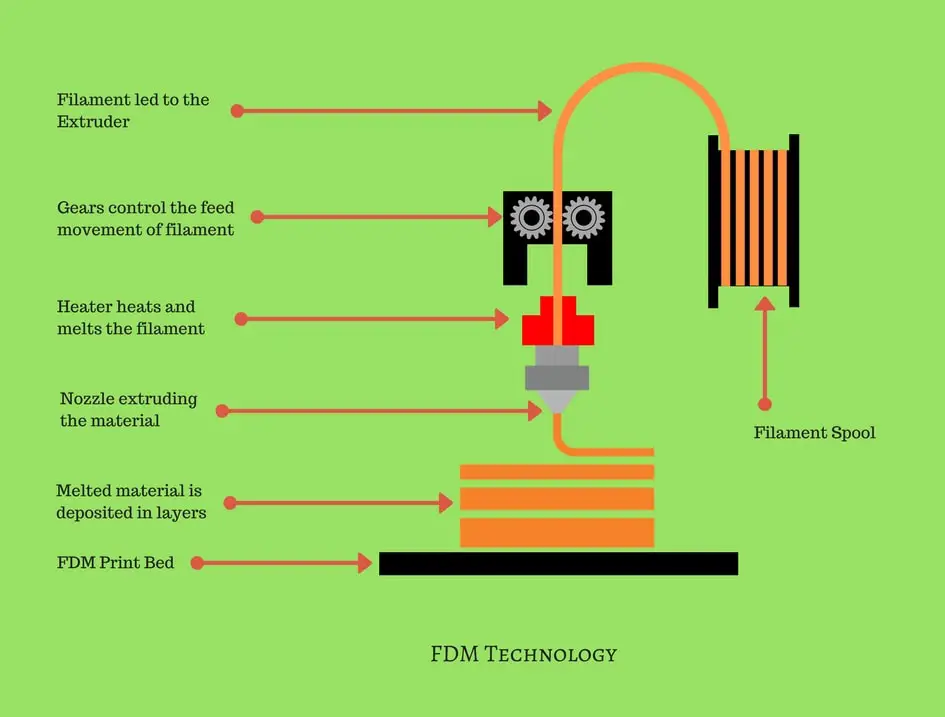

My X5SA is a filament based printer, meaning that it operates according to the above diagram. Plastic filament is melted then deposited in a pattern on a layer-by-layer basis. I struggled largely with the hotend, which is the part that melts the filament before it enters the nozzle.

Here you can see my stock hotend. It typically mounts through the heatsink, but as you can see, the bolts included were too short, and the brass offsets that they screwed to were too poorly made, and I had to countersink their bores to get it to mount. Additionally, I dealt with blobs of plastic from poor mating surfaces between the Bowden tube and the hotend, melted plastic from the heater, and other issues.

While I did have some successful prints, the surface quality was poor. I believe this was due to poor material flow through the nozzle and hotend. I was simply not confident in the printer’s capabilities.

Finally, I snapped off the thermistor which controls the PID heater of the block and I knew it had come time for an upgrade.

The Path Forward

After doing research online, I came to a realization: This printer was not capable of producing acceptable parts with its stock hardware. It’s firmware is apparently inadequate as well.

I found the communities of people owning these printers. The consensus is that the base kit for the machine is essentially the starting place for anyone wanting better prints. To hear many of them talk, the best results is from only keeping the aluminum extrusion frame that the printer comes with and replacing everything else.

With this new knowledge, I ordered replacements for the printer bed and the hotend. I ordered the E3D V6 hotend, the most popular out there, and an upgraded bed from TronXY themselves, which was magnetic and flexible, coated with a superior material for printing.

However, mounting my upgrades was going to be difficult. The new hotend needed a custom mount. The best way to get a custom mount that would fit on my X5SA would be to 3D print one, but I need my new hotend to print it. Catch-22

Fortunately, toxic fumes to the rescue!

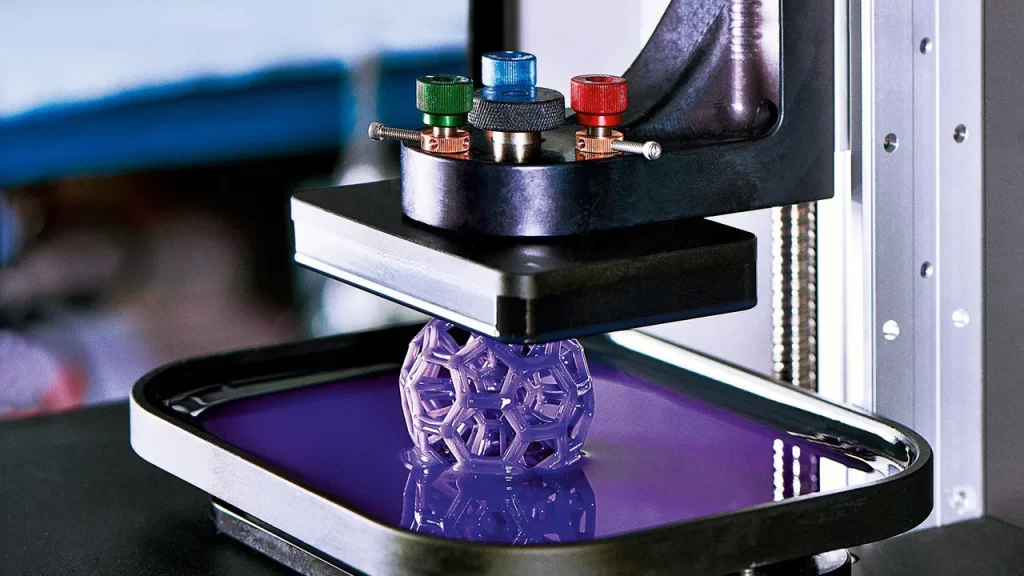

A couple friend of mine decided to have a baby. To their loss and my gain, the resin used in SLA printing is potentially toxic and they wanted the printer out of the house while the wife is pregnant. As the good friend I am, I swooped in with a cash offer of well-below market value for their printer and I was off to the races.

The Elegoo Mars 2, the printer in question, is a MSLA printer. It uses a UV cured resin along with an LCD screen to cure the resin in pixelated layers. The effect is pulling a solid object out of the gloop that is the UV cure resin.

The benefits of this type of 3D printing is its precision, it is much easier to craft complex structures. Additionally, the print time is only dependent on the number of layers – you benefit from increased efficiency by packing the parts in.

After struggling with the filament printing, I was nervous about diving into a completely new style. However, for me, it instantly worked incredibly well. Within half an hour of setup, I had my first print going and it came out incredibly well. Another benefit of resin printing is the surface finish, it was much smoother and more professional looking. I was in business.

Results, at last

Here, finally, is the X5SA with a suite of new upgrades. The hotend is mounted with the resin-printed parts, in gray. I also mounted the new PEI coated bed magnetically below. And while you may see a little stringing, the quality of the prints are markedly improved. Putting the printer back on its sturdy workbench and tuning the temperatures will, I believe, finalize a great system.

(A funny story about the temperature. After replacing the hotend, which includes a new thermistor, the hotend was reading a temperature of 288 Celsius at room temperature. Turns out there was a short in the wiring, quickly resolved after hours of Googling then loosening a single screw.

My first few prints with the new upgrades have gone really well. Now that I have the compounding effect of two 3D printers, I have a list of mods to implement. Look forward to more posts!